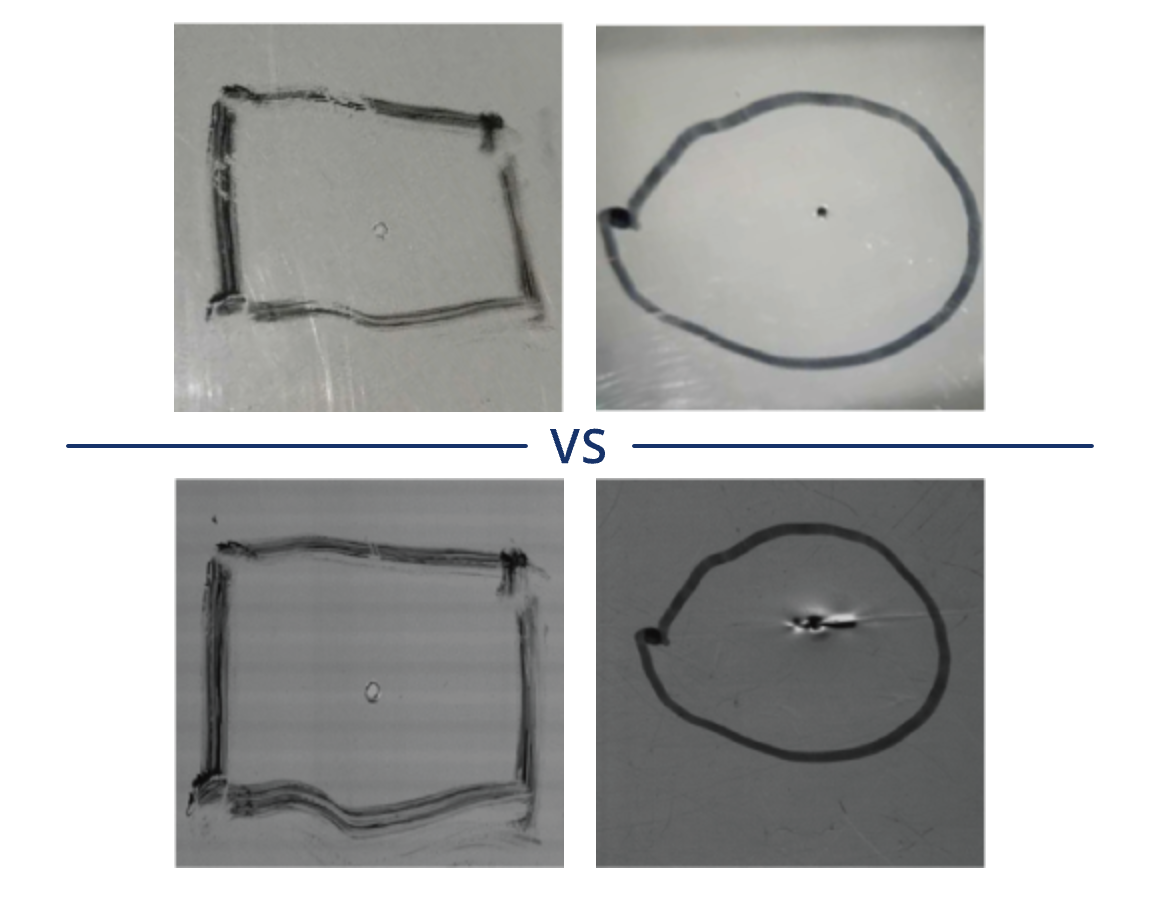

- Up: General Floor Solution

- Down: Leaper Stereo Solution

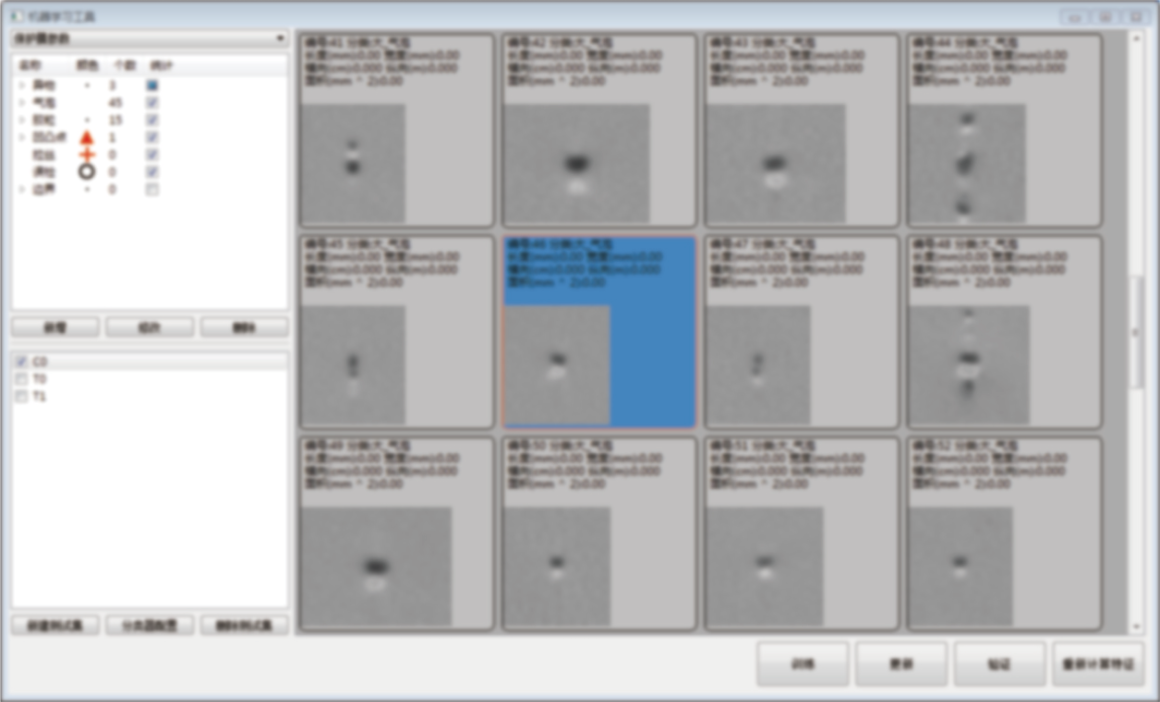

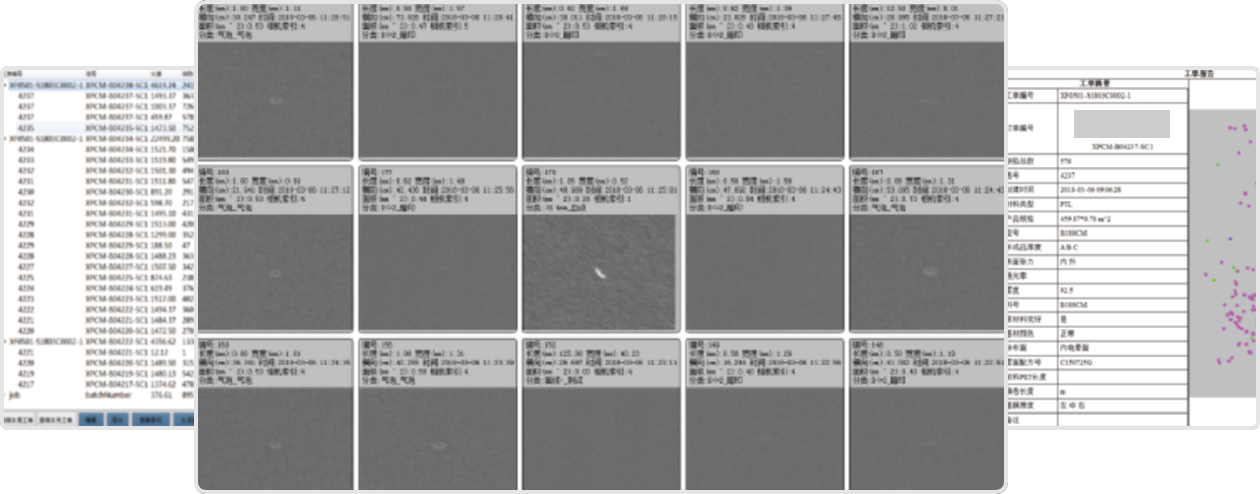

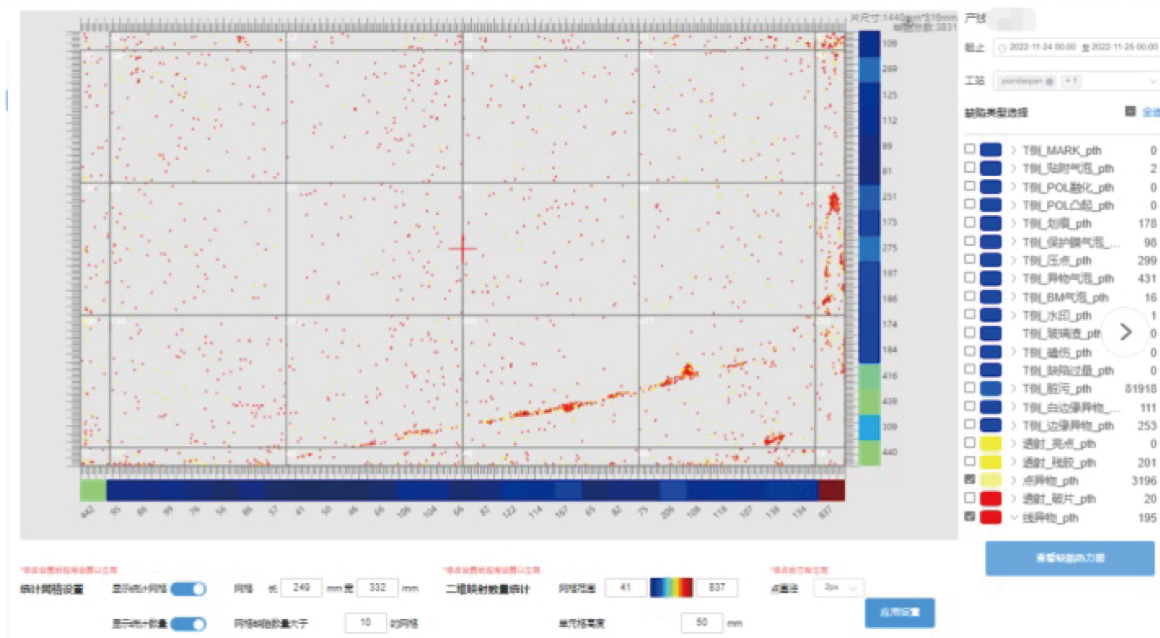

Self-developed machine learning algorithm, can accurately classify defects and present three-dimensional effect, reducing the false defect detection rate.

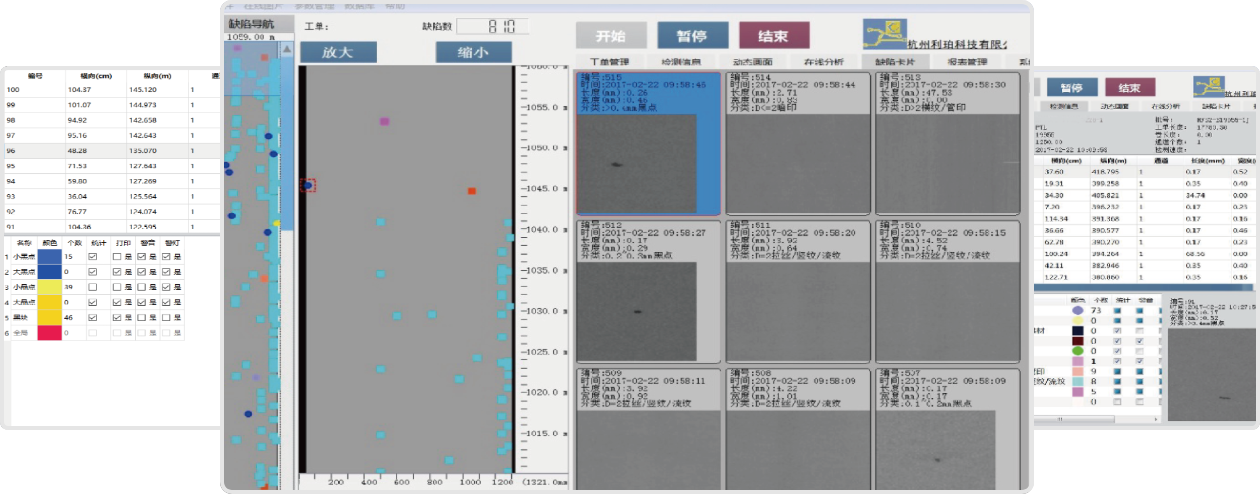

The highest detection accuracy of current products can reach 20μm/pixel, and the fastest speed can reach 500m/min.

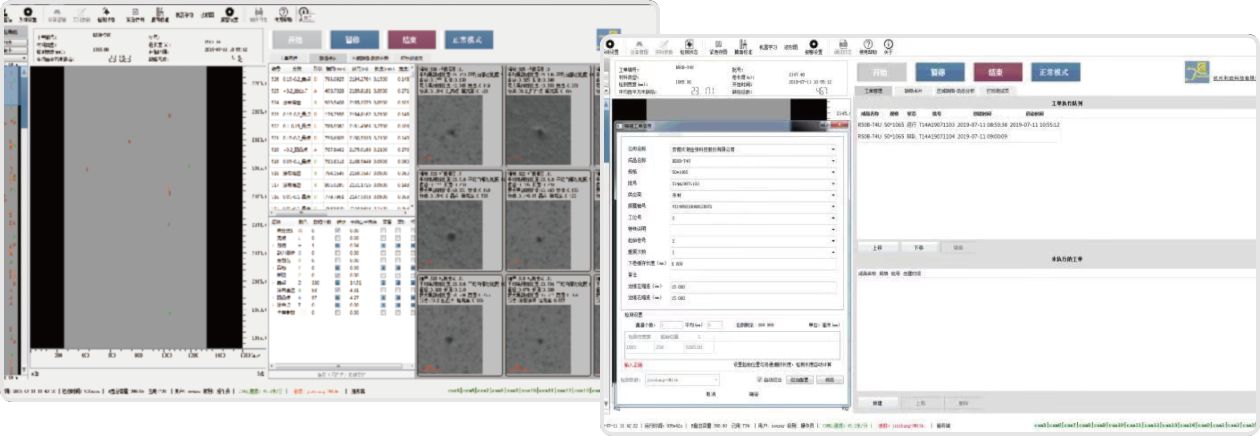

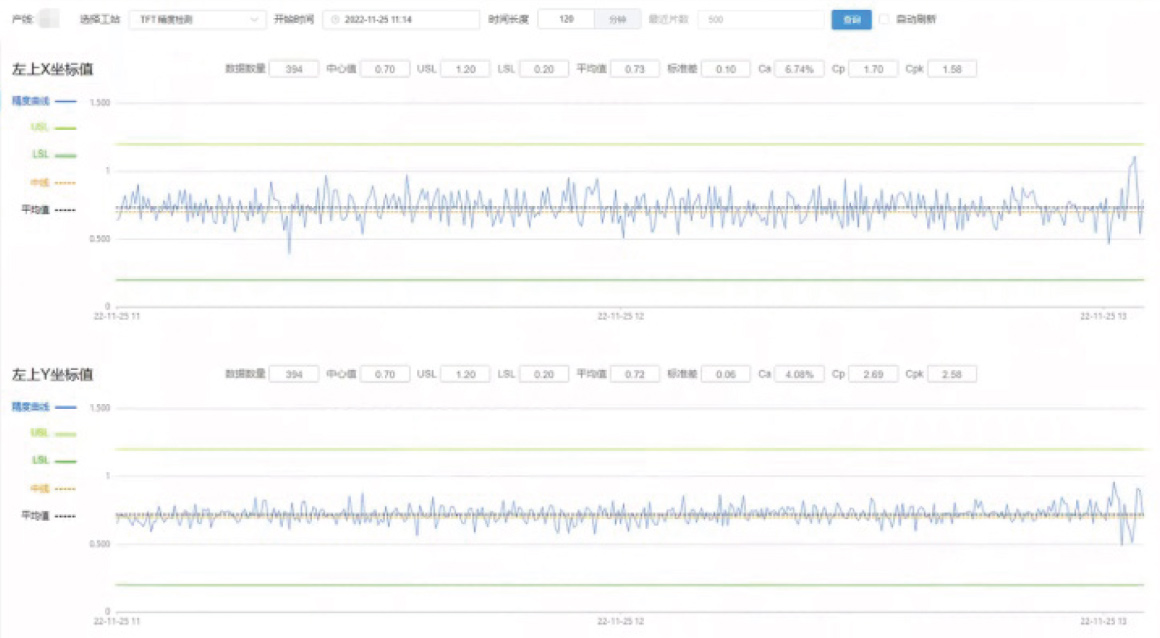

LEAPER product inspection system can view product testing data reports at any time to provide data support for process improvement.