Leaper WaferScan Toolkit (

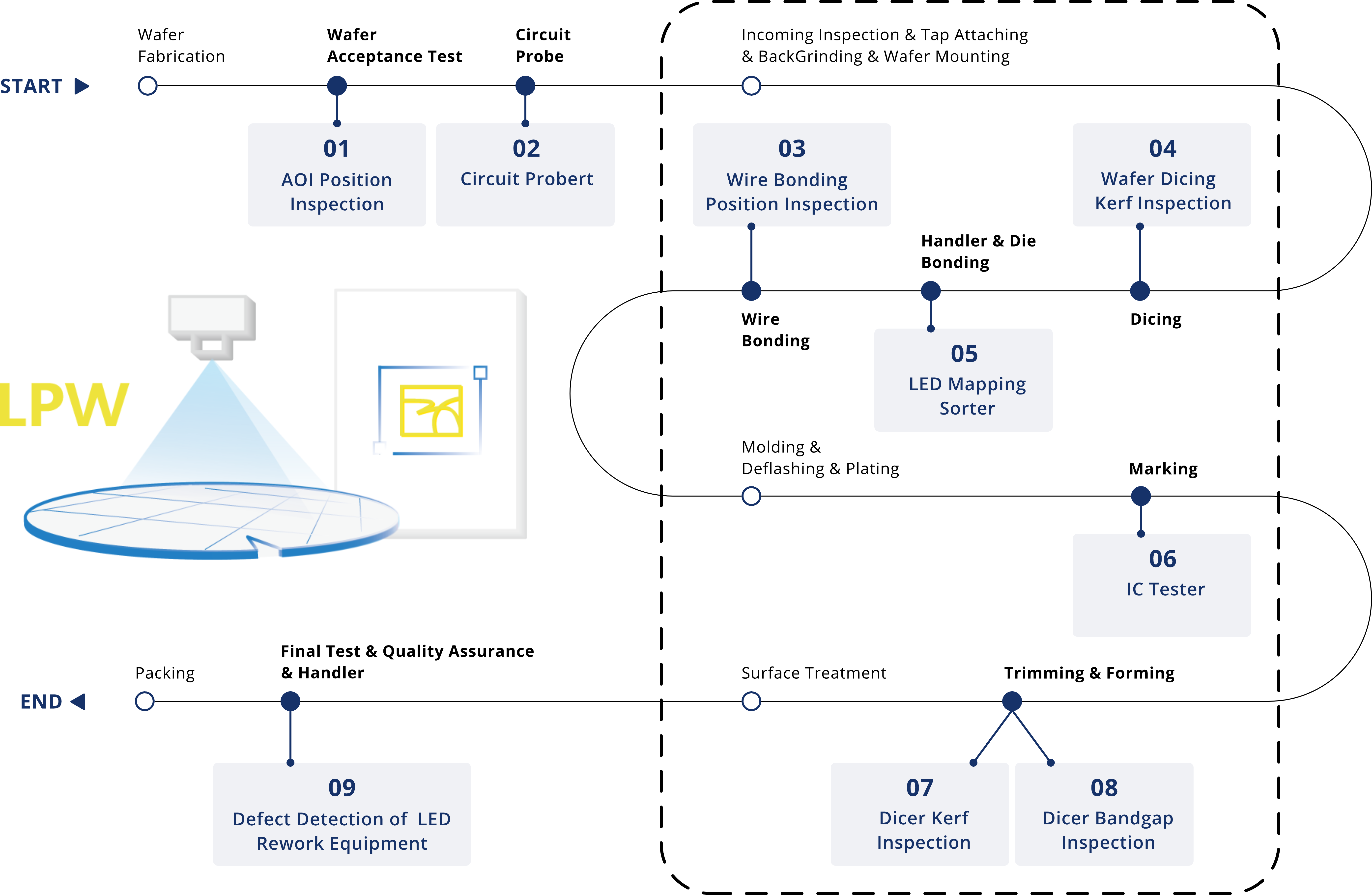

LPW: Main Page (intelliblink.com)) is designed to help user build the widest range of machine vision applications with ultimate flexibility. LPW allows developers to write their own vision processing, configure multi-threading, and access all tool properties and options. Cost-effective, high-quality production of semiconductors and LEDs require speed, accuracy and frictionless tracking through the whole fabrication. Semiconductor manufacturers and OEMs rely on LEAPER machine vision technology to ensure precise alignment of wafers during sorting, counting, masking and etching processes, increase traceability of wafers and die as they move through the front and back-end processes, and improve product quality through advanced inspection procedures.