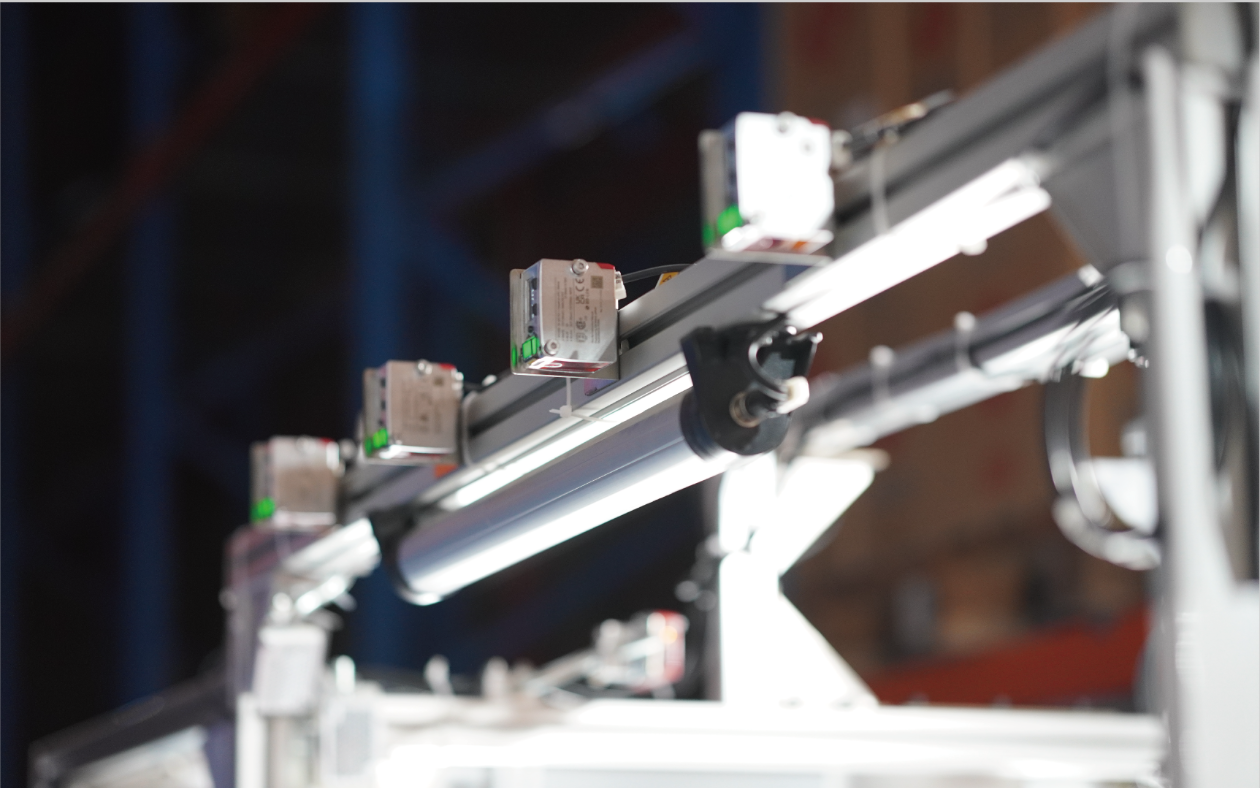

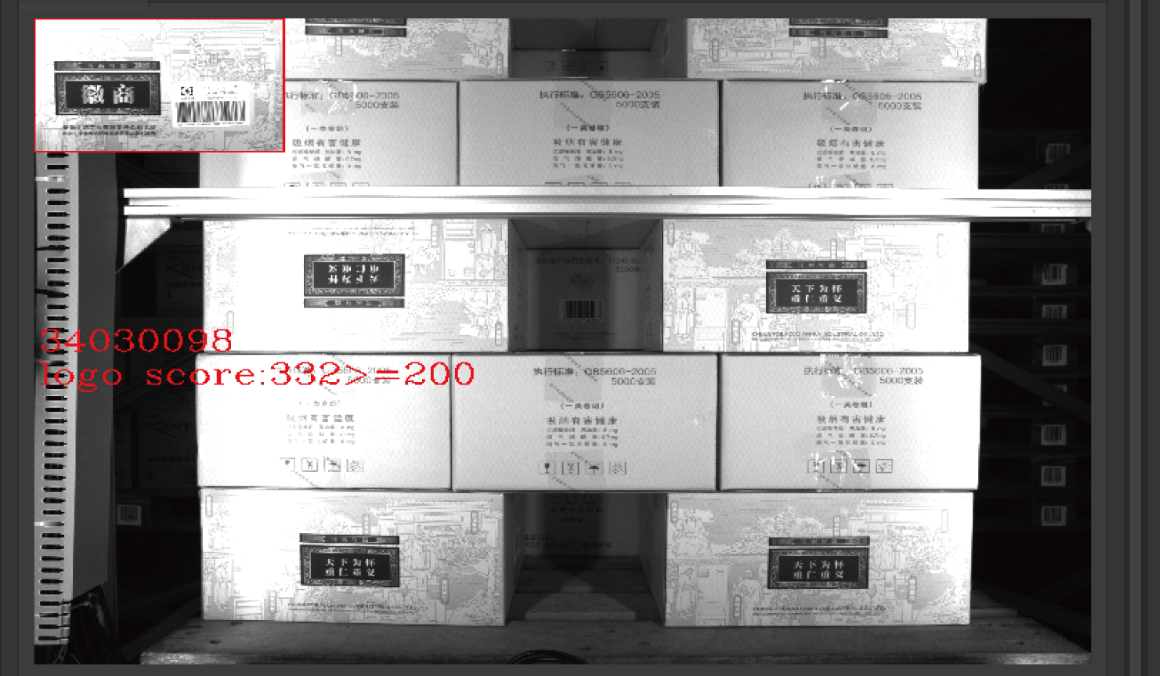

C.Automated Sensing Of Cargo Information

Relying on the AI Cloud technology framework, the parcels are automatically weighed, volume measured, barcode identified, and the data is fused and then transferred to the system server.

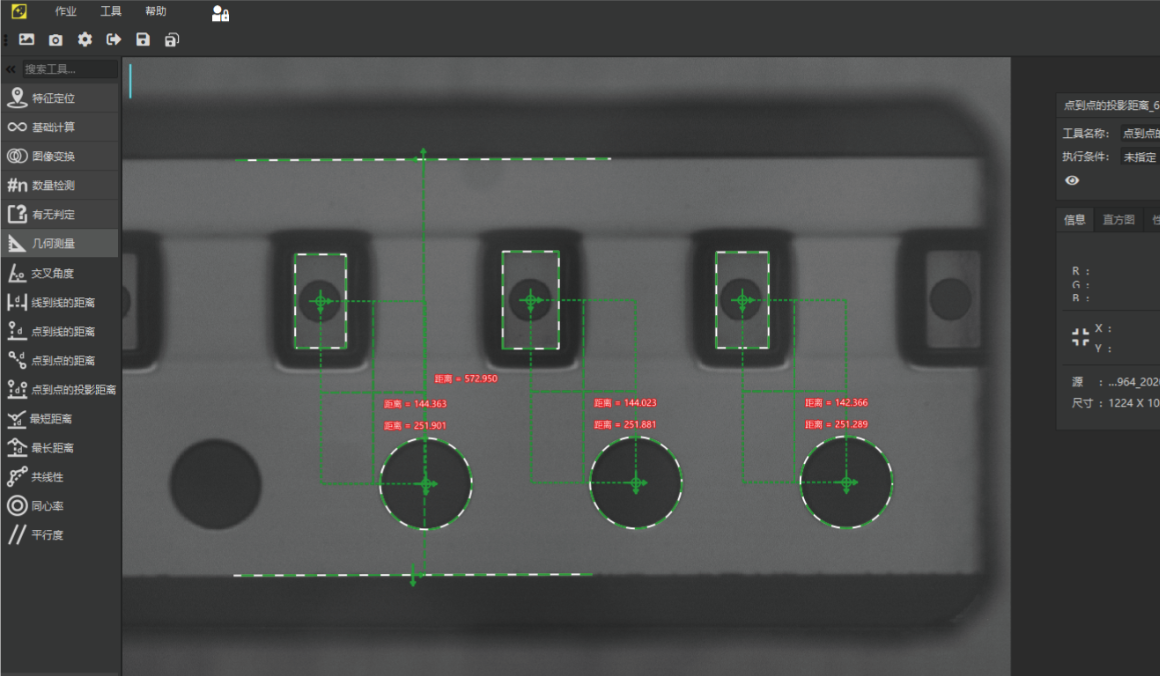

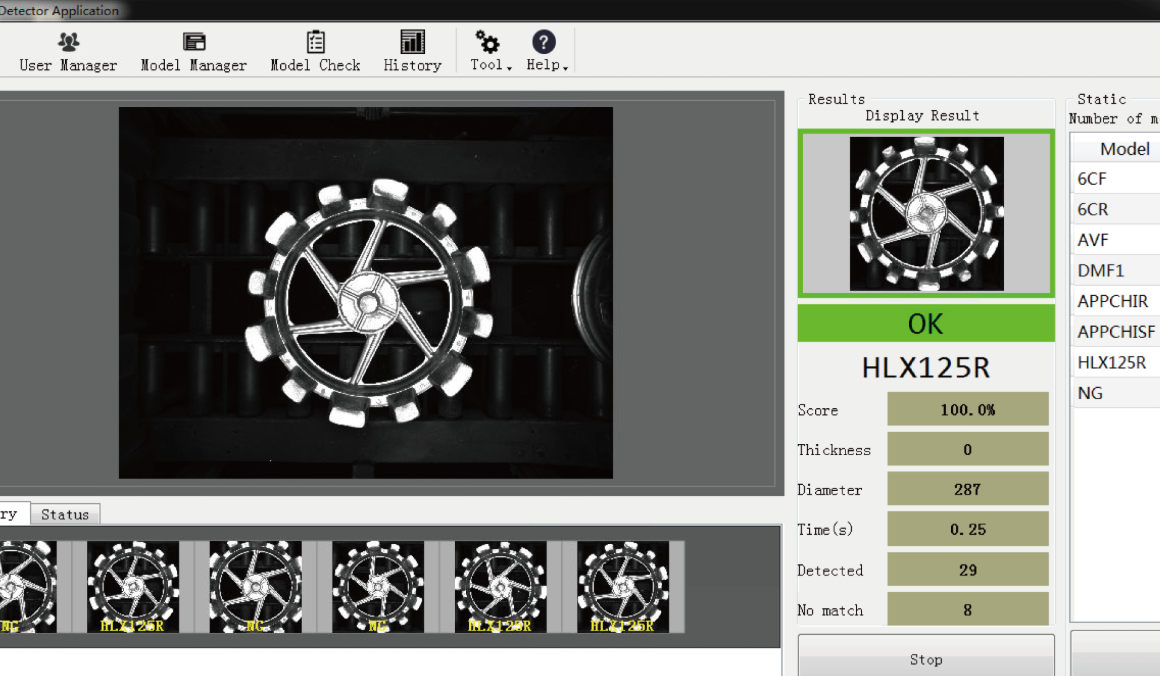

D.Parcel Identification

LEAPER relies on deep learning algorithms and active binocular imaging technology using self-researched intelligent stereo cameras to accurately locate and identify parcels, realizing automatic parcel classification, separation, and uppacking.