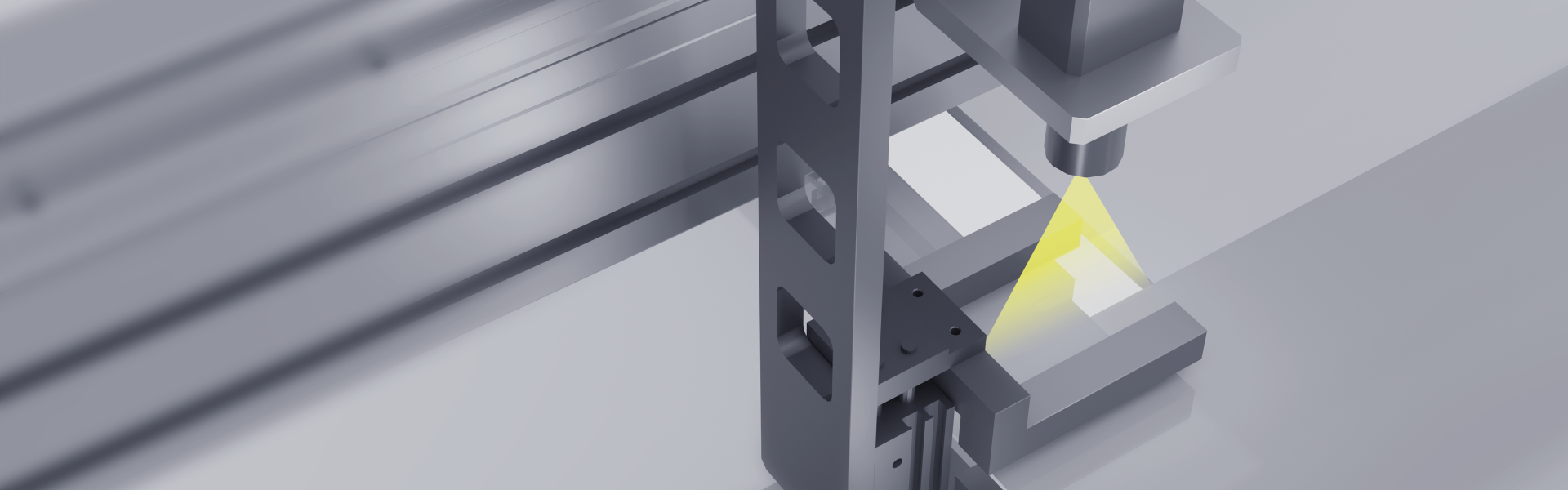

This equipment adopts self-developed machine vision technologies and aluminum alloy frame, which can intelligently identify dozens of defects such as abnormal spots, particles, dents, breaks, stripes, uneven coating, scratches, cracks,etc. that exist in flat materials, accurately record the location information of defects on the surface of flat materials, present and print the size and location of the recorded defects in the form of reports, and realize the online flat material automation and intelligence of inspection, forming a unified standard for product quality inspection of enterprises.

Inspection Content

· Spot defects:Black spots, white spots, crystal spots, abnormal spots, particles, dents, holes, impurities,greasy dirt, etc.

· Linear defects:Fine lines, scratches, folds, cracks, flaws, scratches, etc.

· Surface defects: stripes, uneven coating, film surface piebaldness, flow lines, peeling, roll marks, etc.

Applications

· Optical films:Suitable for diffusion films, brightening (prism) films, polarizing films (polarizers), DOP, POP, QD, fenestrated membranes and other materials.

· Functional films:Suitable for solar backsheet, PVDF, EVA, PE/PET, PP,BOPP/BOPET, PVC, hard coat films and other materials.

· Metal strip:Suitable for aluminum foil, copper clad laminates, copper foil, metal coating and other materials.

· Other film materials:Suitable for lithium-ion battery separators, textile fabrics and other materials.