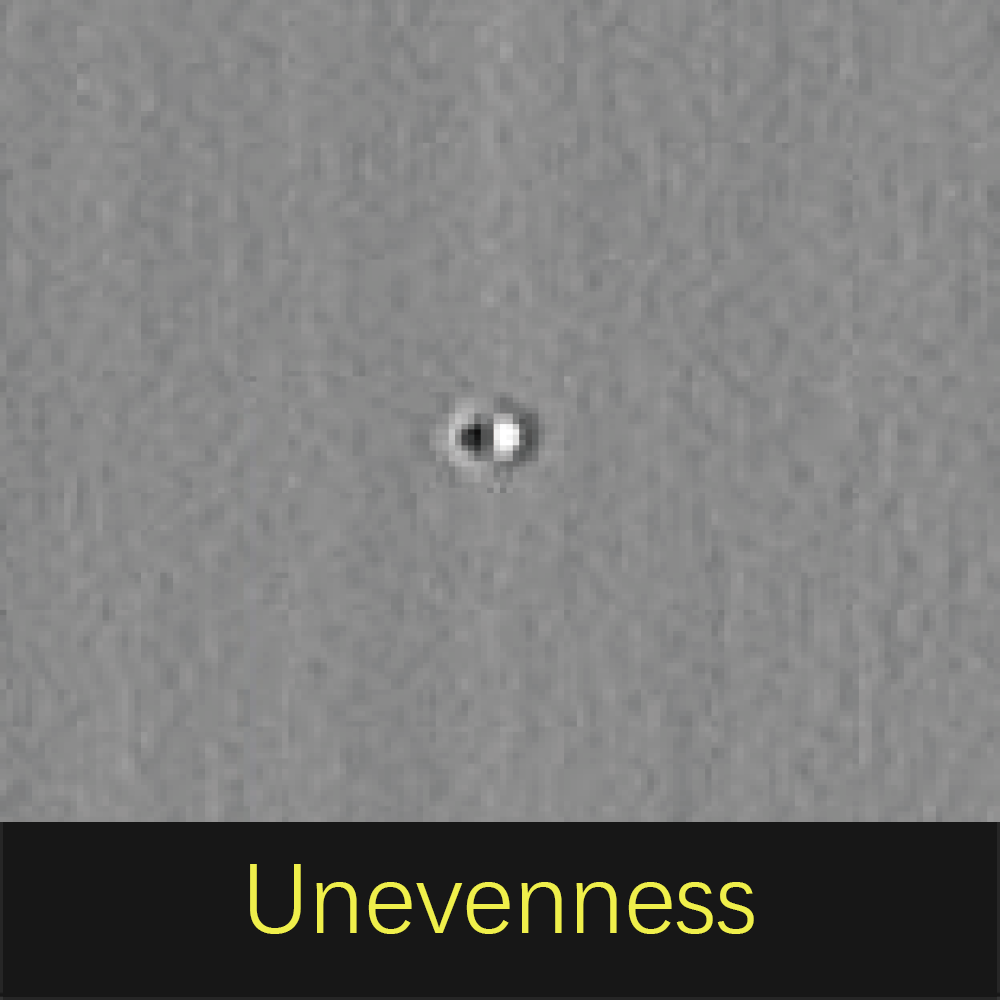

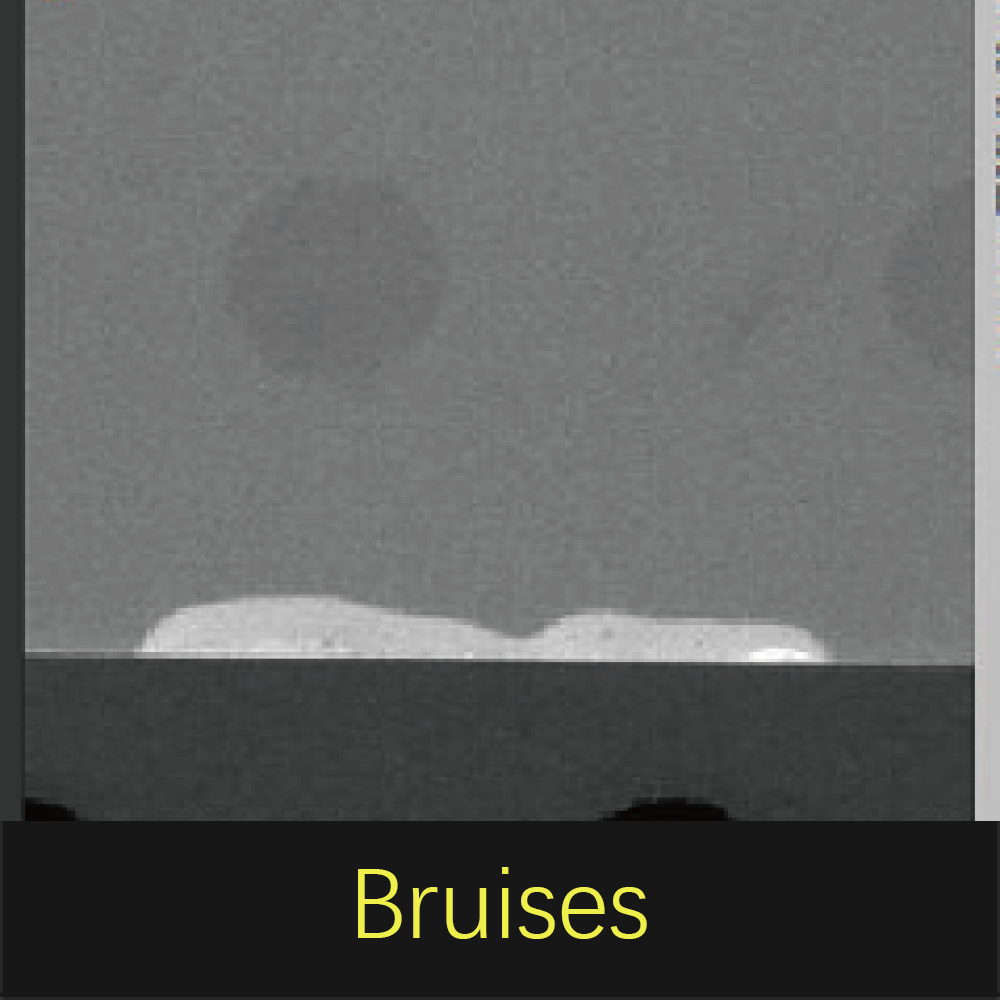

This equipment is used for polaroid detection, and equipped with the automatic loading and unloading device, special conveyor and self-developed AOI detection software, to accurately detect defects such as arrow stamps, defect marks, abnormal matters, bubbles, scratches, unevenness, creases, bumps, residual glue and dirt, separate OK/NG products and thus control the quality of shipped products.